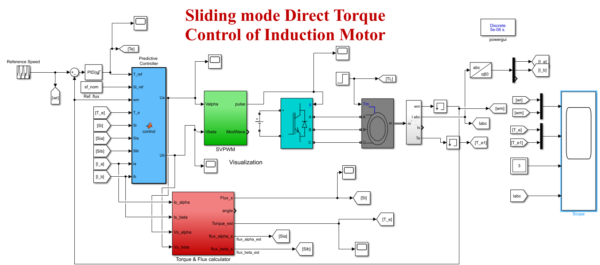

Sliding mode Direct Torque Control of Induction Motor

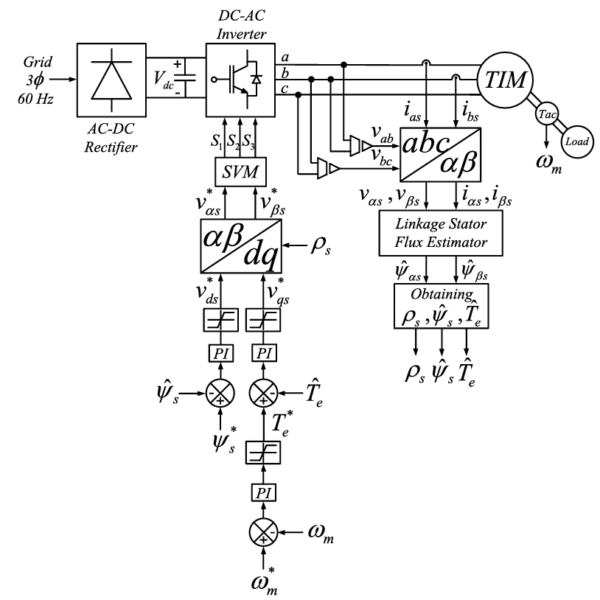

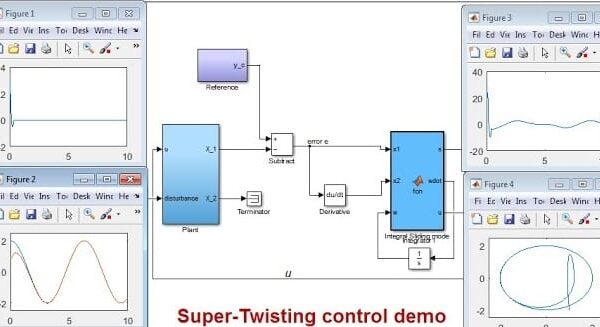

Sliding Mode Direct Torque Control (SM-DTC) of an induction motor enhances traditional DTC by replacing hysteresis controllers with sliding mode controllers (SMC) to reduce torque/flux ripples and increase robustness against parameter variations. It offers fast dynamic response, lower total harmonic distortion (THD), and, in many cases, constant switching frequency.

- Reduced Ripples: Unlike conventional DTC, which uses hysteresis comparators resulting in high torque/flux ripple, SM-DTC uses a smooth sliding surface to reduce these ripples.

- Robustness: SMC provides strong, reliable control even under varying motor parameters and load disturbances.

- Reduced Switching Frequency Variations: The approach helps to stabilize the inverter switching frequency, decreasing acoustic noise.

- Methodology: It involves designing two distinct sliding surfaces for flux and torque control, using Lyapunov stability theory to design the control signals.

- Implementation: Often simulated using MATLAB-Simulink to confirm enhanced transient performance and lower overshoot compared to classic DTC.

Reviews

There are no reviews yet.